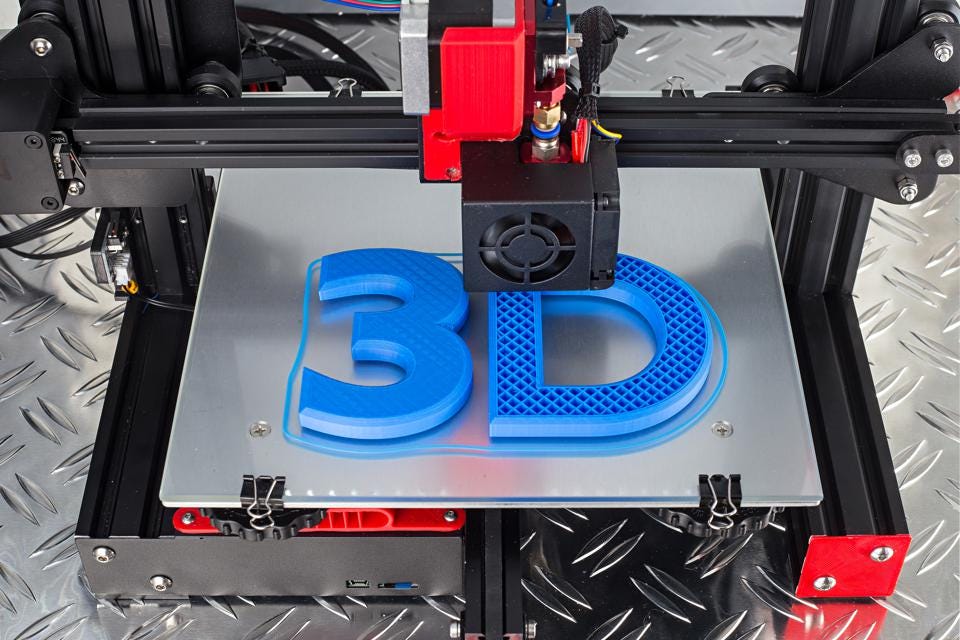

3D printing is an innovative technology that allows companies to turn digital files into physical objects. It provides a cost-effective alternative to traditional manufacturing methods.

Rapid prototyping is a key application of 3D printing in the industrial goods sector. It enables engineers to modify designs individually without needing costly and time-consuming tooling production steps.

Automotive

Automotive is one of the industries where 3D printing has had a profound effect. According to Wohlers Report, motor vehicles accounted for 16.1% of all 3D printing expenditures in 2015.

In the automotive industry, additive manufacturing has numerous applications that support product development and production. 3D printers are employed for rapid prototyping new designs and parts using additive processes.

These prototyping prototypes enable engineers and designers to verify geometries and functionality. This helps minimize design iterations, lead times, and costs associated with production.

Another notable application of 3D printing in the automotive industry is to manufacture tooling aids, such as jigs and fixtures, used throughout production. These tools are significantly lighter and more ergonomic than their traditional counterparts, saving time and money on factory floors.

Aerospace

3D Printing’s potential in aerospace is immense. From custom tooling to tools that can be used in space, additive manufacturing promises to revolutionize how aerospace embraces its future.

Aerospace is an industry that manufactures flight vehicles, aircraft engines and other components necessary for flying airplanes and spacecraft. It provides significant employment opportunities in many countries around the world.

Many aerospace companies rely on 3D printing technology to fabricate parts necessary for aircraft production. This process enables them to craft intricate designs that would be impossible with traditional techniques, while simultaneously cutting costs and expediting production times.

Medical

One of the most prevalent applications of 3D printing in medicine is manufacturing custom surgical instruments like forceps, hemostats, scalpel handles and clamps with this technology. This helps surgeons perform better in the operating room, reduce surgery time and ensure better surgical outcomes for their patients.

Another crucial application is tissue engineering, which creates artificial living tissues that replicate natural human body tissues. This can include blood vessels, heart valves and organs such as kidneys.

On-Demand Manufacturing

The future of 3D printing lies in on-demand manufacturing, where companies can produce spare parts as needed instead of keeping them in inventory. This saves time, money and energy while creating a more efficient supply chain.

Rapid prototyping is a key application of on-demand manufacturing in the industrial goods sector, allowing designers and engineers to make adjustments more quickly than with traditional production techniques. These innovations can drastically shorten product development cycles.

Rapid prototyping in the medical industry offers low-cost options to develop patient-specific devices like clear aligners. Furthermore, this technology permits manufacturers to optimize their design processes, bringing new products to market much more quickly than before.

Digital Manufacturing

Digital manufacturing brings together information technology (IT) and operations technology (OT), creating cyber-physical capabilities. This enables virtual factories to be designed and optimized, offering scalable agility, flexibility and operational performance throughout the production process.

To achieve this, manufacturers must implement a standardised data foundation that permits the flow of data between people, machines and components. This unified view of the factory – called a Smart Connected Factory – can be utilized to implement advanced capabilities like artificial intelligence (AI), machine learning and IoT device monitoring.

Digital manufacturing also helps streamline processes, save costs and accelerate time to market. It eliminates bottlenecks in production while speeding up production to meet customer demands faster and quickly switch over to new products.